Garage side beam cold bending production equipment manufacturers

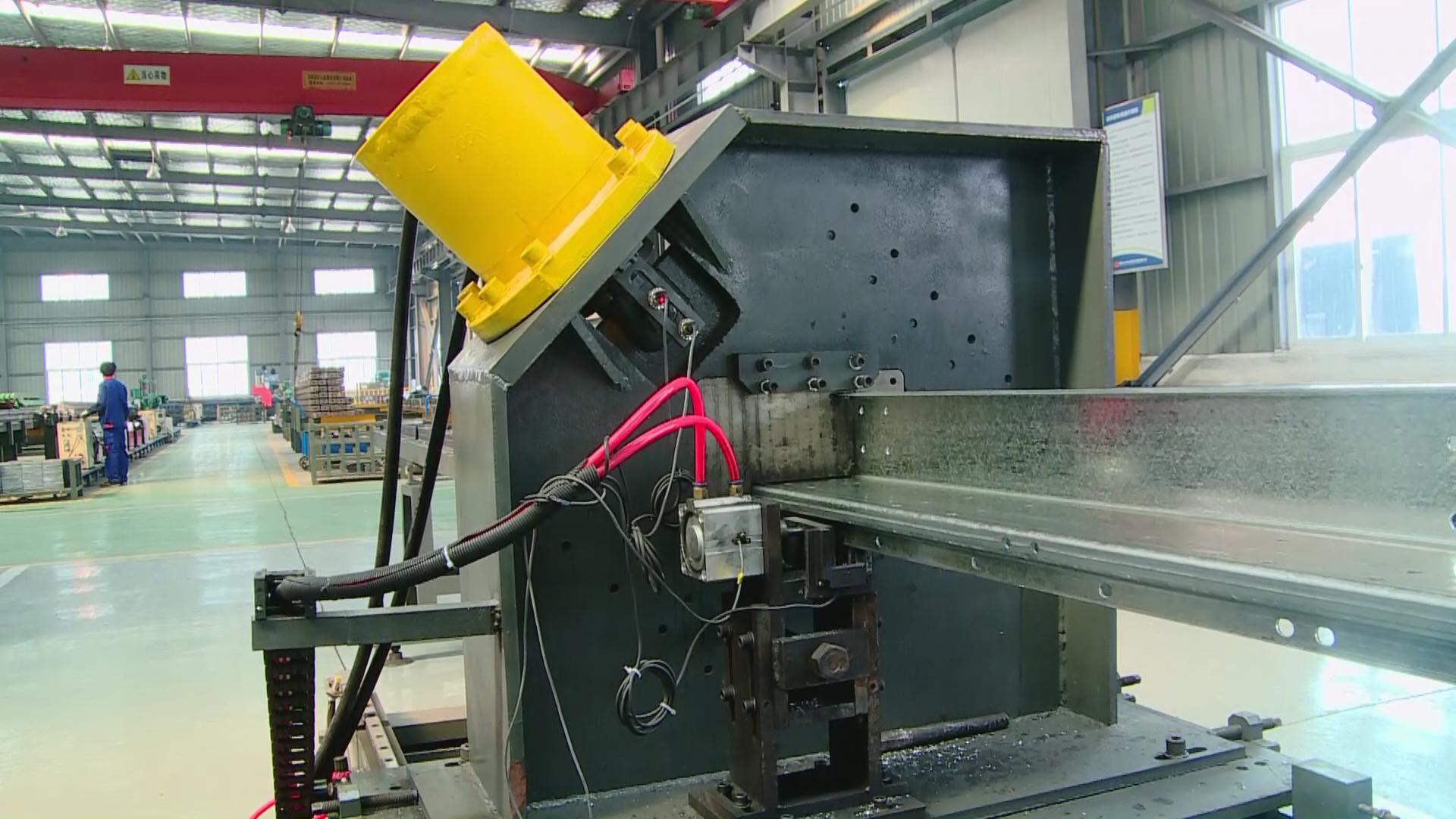

Garage side Beam Cold-bending forming equipment is mainly used for the processing of side beam profiles used in three-dimensional garage assembly vehicles. Because the side beam material is thicker, it has a little weight, traditional processing. Not only is it inconvenient, but it also has to flow through the punching process. Weifang AoTeng Cold Bending Machinery Co., Ltd., after market research and combined with its rich experience in cold bending equipment manufacturing for many years, has manufactured a fully automatic side beam cold bending production equipment with punching and forming, which is efficient and labor-saving, and has simple process. Many well-known garage companies in China recognize and purchase and use!

Part parameters for garage side beam cold-bending production equipment:

< p="">Beam beam cold bending equipment process flow: feeding (manual) - sheet leveling - servo feeding CNC punching - cold bending forming - profile straightening - hole measuring length - hydraulic automatic cutting - unloading (manual) → Transfer to the next processPerformance characteristics:

1. The cold-bending molding layout and equipment structure design of the equipment are scientific and reasonable, and the steel belt is suitable for a wide range of softness and hardness. Corrugation and tearing will not occur during the process;

2. Through servo control, combined with high-speed hydraulic punching mechanism, steel strip punching, and then continuous cold-bending rolling, can punch according to requirements And punch, and ensure accurate size Degree; and high productivity;

3. Reasonable layout, buffering device before and after punching, servo feeding punching, cold bending forming, hydraulic cutting without stopping, improve production efficiency;

4 The operator needs one person;

Technical parameters of the side beam cold bending equipment:

1. The length of the production line is 50 meters;

2. Production speed 0-4 m/min adjustable;

3. CNC cylinder frequency more than once per second;

4. CNC punching motion CAD flexible control, computer programming, online input, processing , memory function;

5. Host PLC control, color touch screen can directly input data, control host action;

6. Adjust to meet different specifications of side beam profile rolling, Achieve a multi-purpose machine;

1, zui overfeed width: 600mm;

2, rolling thickness: 4 mm ;

3, Operator: 1-2 people

4, Rolling pass: 20 channels;

5, Spindle diameter: ф100 Mm;

6, small spacing of upper and lower axes zui: 200mm;

7, main motor power: 18.5KW×2

8, ;The upper and lower axes zui large spacing: 400 mm;

9, Total power of the unit: 80.5KW (excluding gas source);

10, Others : Power: AC380V Air source pressure: 0.6MPa

<>