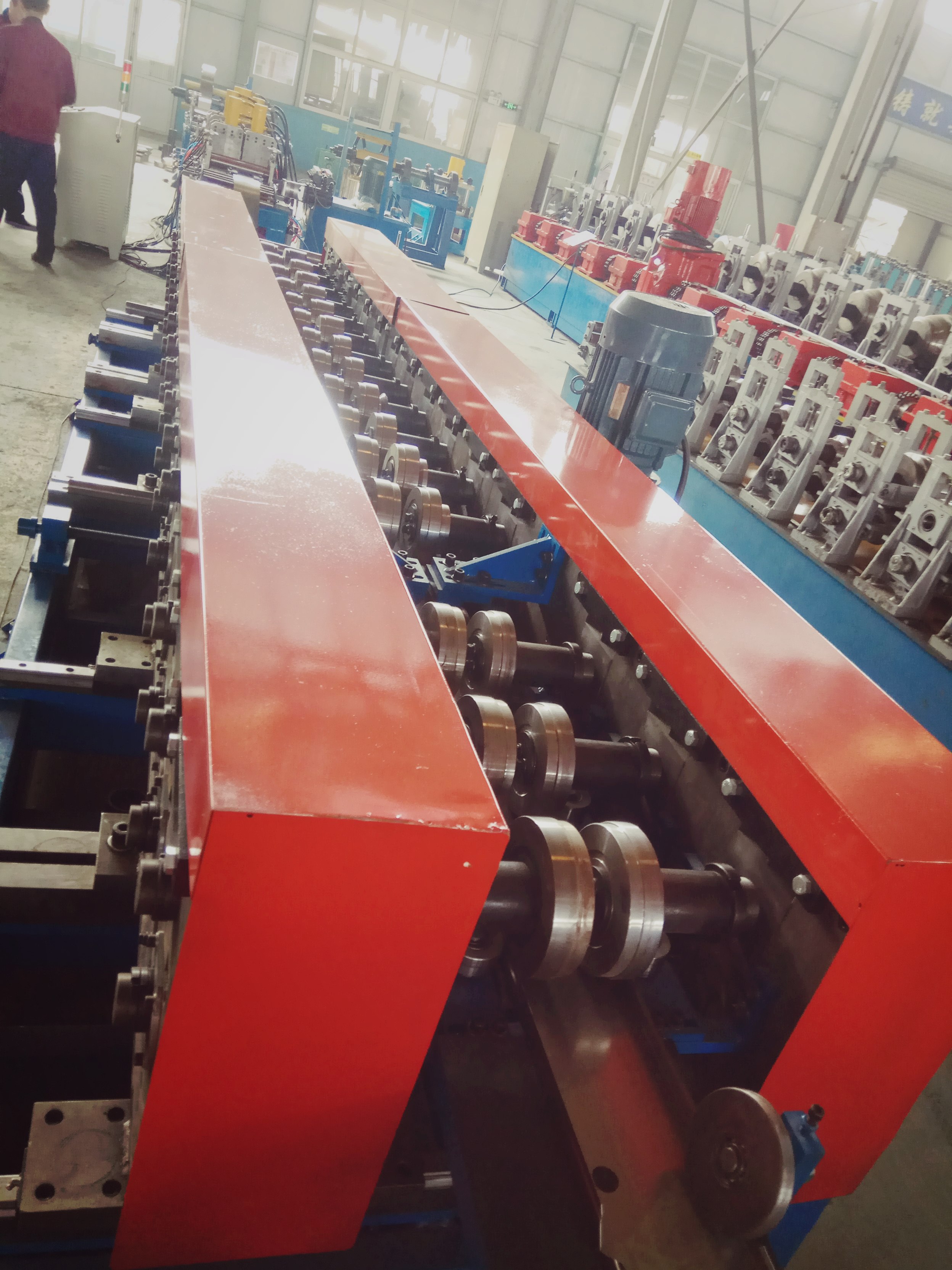

Fire box body molding machine

Fire Box Forming Equipment Manufacturer: Weifang, Shandong Oteng Cold Bending Machinery Co., Ltd. Model: AT-240

The manufacture of the fire box body molding machine has high requirements on processing precision and design capability. Our company is engaged in cold bending machine manufacturing. In the past 20 years, there is a wealth of manufacturing Test. And processing strength, perfect after-sales service. At present, we have successfully delivered a number of high-quality fire box-in-one molding machines to our customers, creating a greater cost advantage for our customers and providing a strong guarantee for better market development.

The process of processing the fire box body is cumbersome, time-consuming and laborious, and the cost is high. Weifang AoTeng Cold Bending Machinery Co., Ltd. manufactures punching and forming automatic production equipment which is well adapted to the needs of the market, and has seized market share for customers and created a price advantage. Our fire box case is not only solved once. Labor costs have saved a lot of workers' wages. What's more important is that the products manufactured by our fire-fighting cabinets are more standardized, and the finished products are also very uniform. In general, after investing in equipment, your profit margin is bigger, the products will be more beautiful, and provide strong support for market development!

Partial parameters of the fire box body molding machine:

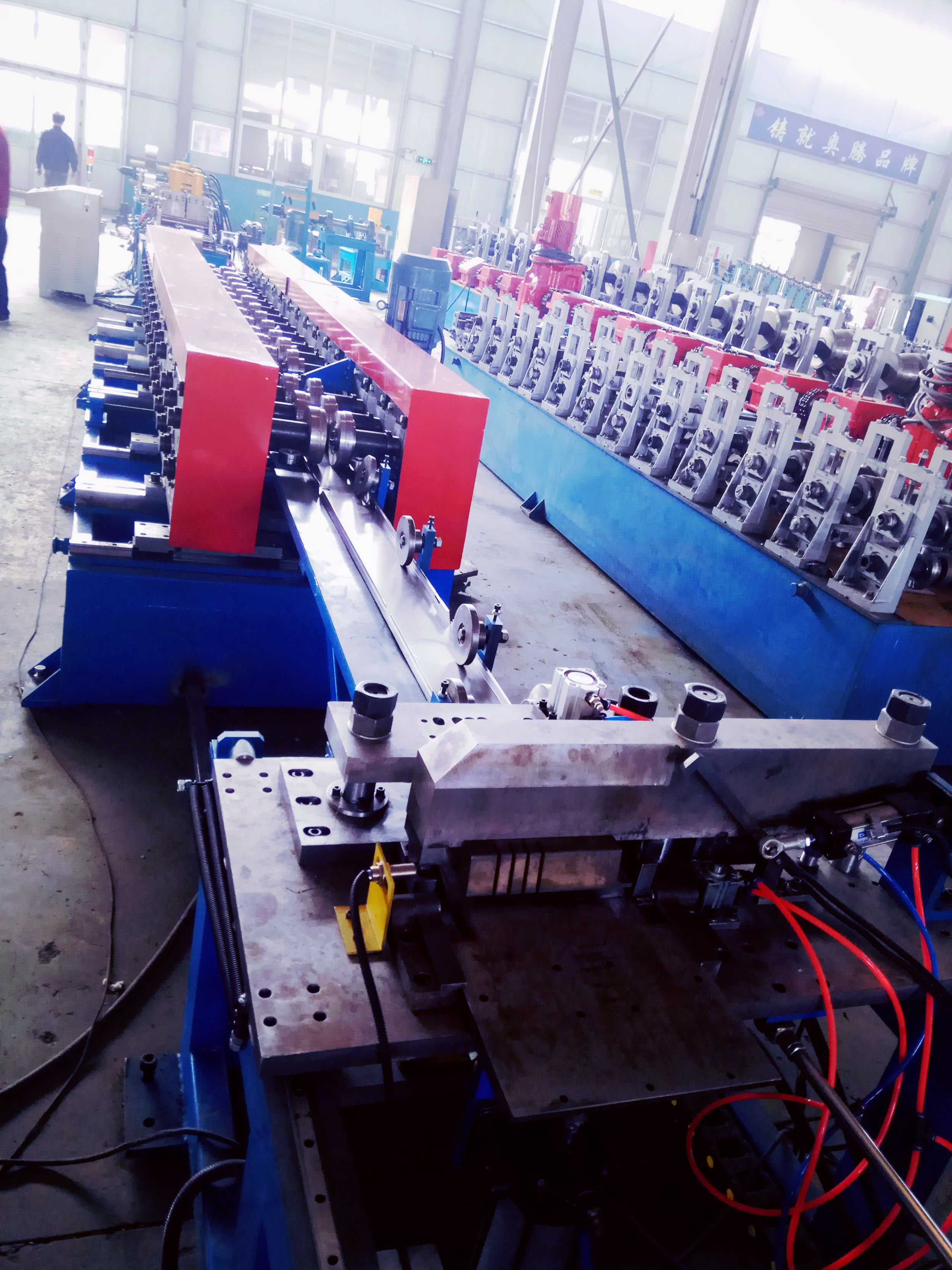

Process: Unwinder-leveling machine- Servo feeding hydraulic punching-cold bending forming-automatic bending-cutting

Material material: ordinary cold-rolled steel plate, stainless steel, etc.

Steel strip thickness: 0.6~2 mm (range)

Steel strip width: According to fire box size specifications

Production speed: about 100 boxes // hourly

Total motor power: about 25.5kw<>

Hydraulic station power: 5.5kw

Cutting method: hydraulic shutoff

Electrical control: PLC

Drive motor: variable frequency motor drive

Unwinder zui weighing: 4 tons

Air source: 0.6MPa

Voltage parameters: 380V, 50Hz, 3-phase

cut Inch tolerance: ≤ ±0.5mm

Cutting die material: Cr12MoV

roll material: Cr12 quenching HRC58--62°

spindle diameter: Ф55mm or Ф65mm<>